Description

The emulsion air-liquid is pushed into the delivery channel where the air, which is lighter, gets separated and gets out from the delivery piping; the liquid, which is heavier, returns into circulation. Once the pump gets rid of all the air from the suction piping, the pump starts and it works as a normal centrifugal pump, therefore the pump can work also with a mixture of air-liquid. There is a non-return valve fitted to the discharge side which enables a small quantity of liquid to be retained in the pump body thus allowing an automatic prime and suction lift to any application. This eliminates the need to prime the pump at each start up.

Pump Construction

- Pump body, impeller, pump support and inlet in Cast Iron.

- Non return valve in Nitrile Rubber and Steel.

- Mechanical seal in Carbon Ceramic (upon request tungsten/carbide).

- Rotor shaft in Stainless Steel fitted with seal bearings.

- Totally enclosed fan cooled motor (TEFC).

- Single phase motors with a built in thermal overload protection on request, the capacitor is permanently in circuit.

- Winding Insulation to class F.

Pump Technical Data

| Model | JDA100W-A12 |

| Brand | JMS |

| Manufacturer’s Warranty | 1 year Limited Warranty |

| Impeller Material | Cast Iron |

| Port Size (in.) | 3 |

| Max Flow (GPH) | 14400 |

| HP | 9.5 |

| Max. Temperature of Pumped liquid | 15°C to 70°C |

| Motor | YANMAR Diesel Engine L100W |

| Working Range | @ 167 ft. > 1620 GPH @ 43 ft. > 14400 GPH |

| Max. Suction Lift (ft.) | 17 |

| Max. PSI | 72.5 |

| Suction Port (in.) | 3 |

| Discharge Port (in.) | 3 |

| Self-Priming | Yes |

| Start | Electric start / Recoil start |

| Portable | Yes – 2 Wheels Trolley With Handles |

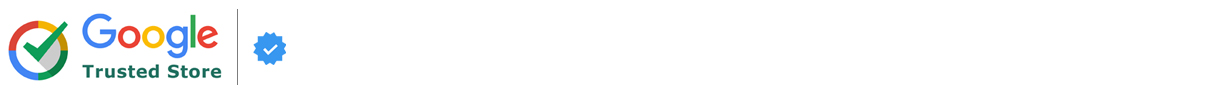

Pump Performance Curve

| Model | Solids Handling | Impeller Diameter | Number of Blades |

| Inch | Inch | ||

| JCS-S3A12S | Ø 0.5 | Ø 7.7 | 5 |

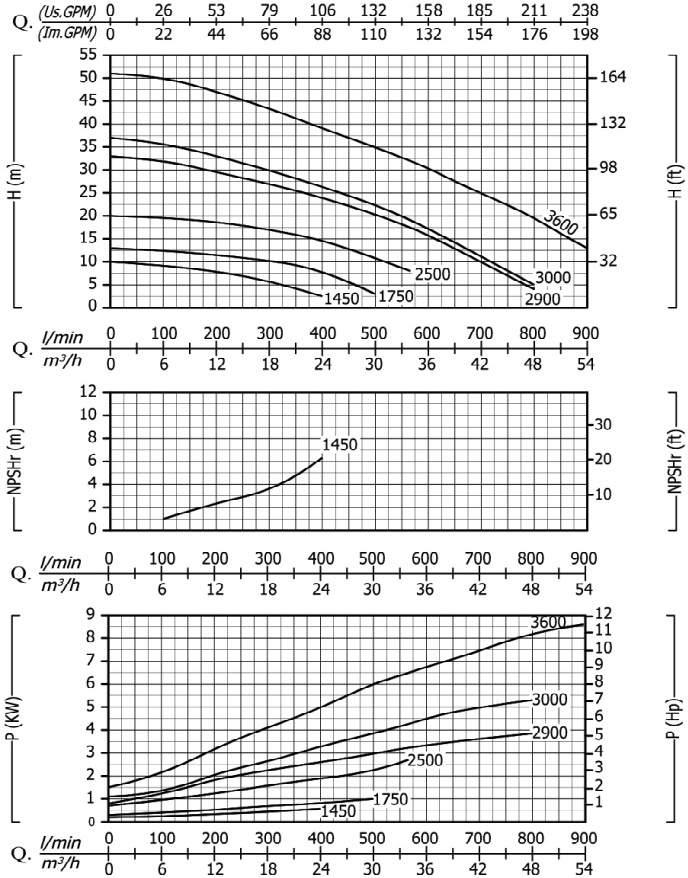

Engine Performance Curve

| Model | L100W | |||

|---|---|---|---|---|

| Type | 4 stroke, vertical cylinder, air-cooled diesel engine | |||

| ATS (After Treatment System) | – | |||

| No. of Cylinders | 1 | |||

| Bore x Stroke | inch | Φ 3.4 x 3 | ||

| Displacement | gallons | 0.1 | ||

| Continuous Rated Output | Engine Speed | rpm (min-1) | 3600 | |

| Output | Kw | 6.2 | ||

| Maximum Rated Output | Engine Speed | rpm (min-1) | 3600 | |

| Output / Eng. Speed | Kw | 6.8 | ||

| High Idling | rpm (min-1) | 3800±30 | ||

| Engine Weight (Dry) | Electric Starter | lb | 117.7 | |

| Recoil Start | lb | 106.7 | ||

| Cooling System | Forced air-cooling by flywheel fan | |||

| Lubricating System | Forced lubricating system | |||

| Starting System | Electric star / Recoil start | |||

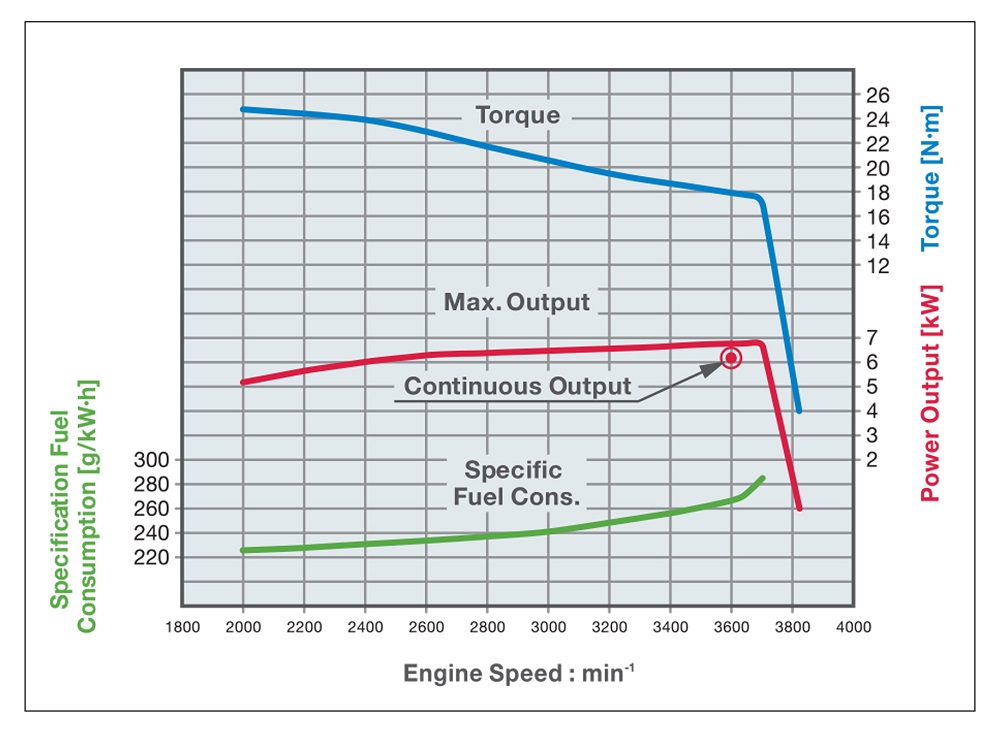

| Dimension | Overall Length (L) | inch | 16.9 | |

| Overall Width (W) | inch | 18.6 | ||

| Overall Height (H) | inch | 19.4 | ||

| Lubricating System | Dispstick Upper Limit | gallons | 0.4 | |

| Dispstick Lower Limit | gallons | 0.3 | ||

| Fuel Oil Tank Capacity | gallons | 1.4 | ||

Engine Dimensions (mm)

Installation

Upon installation always prime the pump body first before start up. Pump must be installed always in the horizontal position.

SHIPPING

SHIPPING PREMIUM DELIVERY

PREMIUM DELIVERY WAREHOUSE PICKUP

WAREHOUSE PICKUP